Introduction

A double layer roll forming machine is a versatile piece of equipment used in the manufacturing industry. It is designed to produce two different profiles or layers of material simultaneously, offering increased efficiency and productivity. In this article, we will explore the various aspects of a double layer roll forming machine and its applications in different industries.

What is a Double Layer Roll Forming Machine?

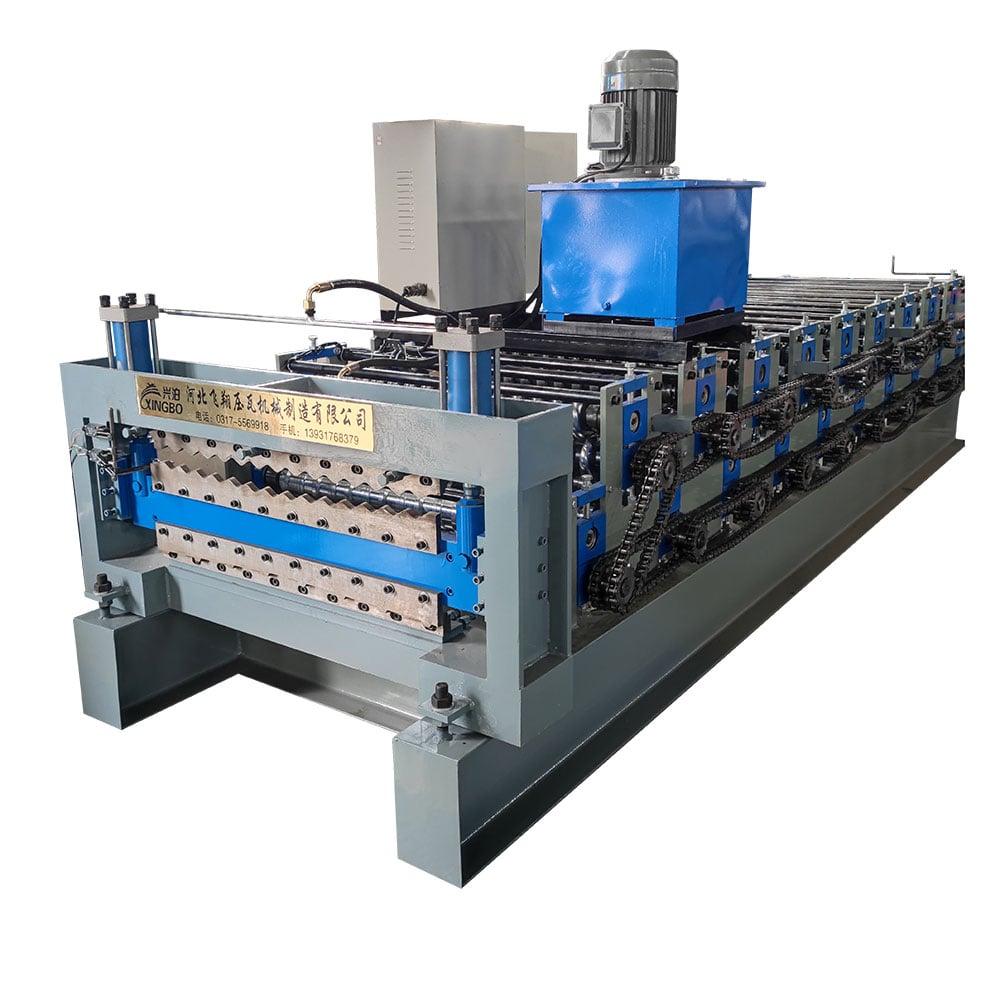

A double layer roll forming machine is a specialized equipment used for continuous and automated shaping of metal sheets into desired profiles. It consists of a series of rollers and dies that gradually bend, stretch, and shape the metal as it passes through the machine. Unlike a single layer roll forming machine, which produces a single profile, a double layer roll forming machine can generate two different profiles simultaneously.

How Does a Double Layer Roll Forming Machine Work?

The working principle of a double layer roll forming machine is based on the concept of continuous bending and shaping of metal sheets. The machine employs a series of rollers, located at specific intervals, that gradually shape the metal sheets into the desired profiles. The rollers are often adjustable, allowing for easy customization of the final product. The metal sheets are fed into the machine, and as they pass through the rollers, they undergo various forming operations, such as bending, stretching, and cutting, to achieve the desired shape.

Applications of Double Layer Roll Forming Machine

Double layer roll forming machines find extensive applications in various industries. Some of the key industries where these machines are used include:

1. Construction Industry

Double layer roll forming machines are widely used in the construction industry for the production of roofing and wall cladding profiles. These machines can efficiently produce corrugated sheets, trapezoidal profiles, and other customized shapes required for building exteriors. The ability to produce two different profiles simultaneously makes these machines highly desirable in the construction sector.

2. Automotive Industry

In the automotive industry, double layer roll forming machines are utilized for manufacturing various components, such as car body panels, door frames, and window channels. The machines can produce complex profiles with high precision, ensuring the desired fit and finish of the final product. The efficiency and reliability of double layer roll forming machines make them indispensable in automotive manufacturing.

3. HVAC Industry

Heating, ventilation, and air conditioning (HVAC) systems often require customized ductwork and other profiles. Double layer roll forming machines are employed to produce these profiles with ease. The machines can form ducts of different shapes and sizes, ensuring a perfect fit for HVAC installations. This reduces the need for manual adjustments and improves overall efficiency.

4. Furniture Industry

Double layer roll forming machines are also used in the furniture industry for manufacturing components like frames, rails, and panels. These machines enable the production of consistent and high-quality profiles, contributing to the durability and aesthetics of the furniture pieces. The flexibility offered by double layer roll forming machines allows furniture manufacturers to meet diverse customer demands.

Advantages of Double Layer Roll Forming Machine

Double layer roll forming machines offer several advantages over traditional manufacturing methods. Some of these advantages include:

1. Increased Efficiency

By producing two different profiles simultaneously, double layer roll forming machines significantly enhance production efficiency. This allows manufacturers to meet higher demand while reducing production time and costs.

2. Cost-effective

Double layer roll forming machines eliminate the need for multiple machines or processes to produce different profiles. This saves on equipment costs and reduces labor requirements, making it a cost-effective solution for profile manufacturing.

3. Customization

With adjustable rollers and dies, double layer roll forming machines offer great flexibility in producing customized profiles. Manufacturers can easily adjust the machine settings to meet specific requirements, allowing for greater product variety.

4. High Precision

Double layer roll forming machines ensure high precision in profile manufacturing. The uniformity and accuracy of the forming process result in consistent product dimensions and quality, reducing waste and improving overall product performance.

5. Time-saving

The continuous and automated nature of double layer roll forming machines saves significant time compared to manual or semi-automated processes. This enables manufacturers to meet tight deadlines and deliver products on schedule.

Conclusion

Double layer roll forming machines are a valuable asset in various industries, offering increased efficiency, cost-effectiveness, and customization options. Their applications range from construction and automotive to HVAC and furniture manufacturing. By understanding the working principle and advantages of these machines, manufacturers can make informed decisions about integrating them into their production processes.