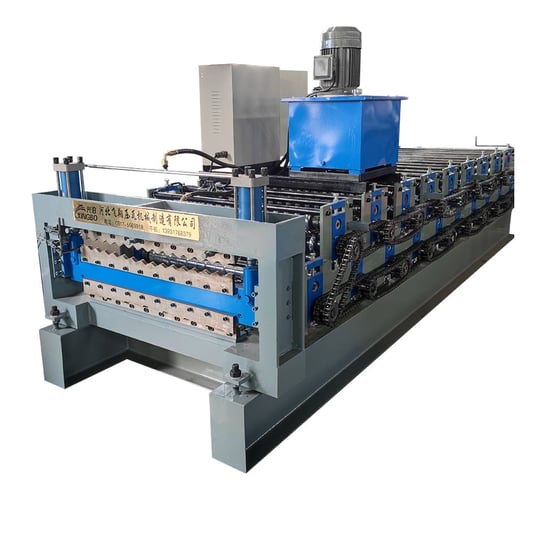

IntroductionA double layer roll forming machine is a versatile piece of equipment used in the manufacturing industry. It is designed to produce two different profiles or layers of material simultaneously, offering increased efficiency and productivity. In this article, we will explore the various aspects of a double layer roll forming machine and its applications in different industries.What is a Double Layer Roll Forming Machine?A double layer roll forming machine is a specialized equipment used for continuous and automated shaping of metal sheets into desired profiles. It consists of a series of rollers and dies that gradually bend, stretch, and shape the metal as it passes through the machine. Unlike a single layer roll forming machine, which produces a single profile, a double layer roll forming machine can generate two different profiles simultaneously.How Does a Double Layer Roll Forming Machine Work?The working principle of a double layer roll forming machine is based on the concept of continuous bending and shaping of metal sheets. The machine employs a series of rollers, located at specific intervals, that gradually shape the metal sheets into the desired profiles. The rollers are often adjustable, allowing for easy customization of the final product. The metal sheets are fed into the machine, and as they pass through the rollers, they undergo various forming operations, such as bending, stretching, and cutting, to achieve the desired shape.Applications of Double Layer Roll Forming MachineDouble layer roll forming machines find extensive applications in various industries. Some of the key industries where these machines are used include:1. Construction IndustryDouble layer roll forming machines are widely used in the construction industry for the production of roofing and wall cladding profiles. These machines can efficiently produce corrugated sheets, trapezoidal profiles, and other customized shapes required for building exteriors. The ability to produce two different profiles simultaneously makes these machines highly desirable in the construction sector.2. Automotive IndustryIn the automotive industry, double layer roll forming machines are utilized for manufacturing various components, such as car body panels, door frames, and window channels. The machines can produce complex profiles with high precision, ensuring the desired fit and finish of the final product. The efficiency and reliability of double layer roll forming machines make them indispensable in automotive manufacturing.3. HVAC IndustryHeating, ventilation, and air conditioning (HVAC) systems often require customized ductwork and other profiles. Double layer roll forming machines are employed to produce these profiles with ease. The machines can form ducts of different shapes and sizes, ensuring a perfect fit for HVAC installations. This reduces the need for manual adjustments and improves overall efficiency.4. Furniture IndustryDouble layer roll forming machines are also used in the furniture industry for manufacturing components like frames, rails, and panels. These machines enable the production of consistent and high-quality profiles, contributing to the durability and aesthetics of the furniture pieces. The flexibility offered by double layer roll forming machines allows furniture manufacturers to meet diverse customer demands.Advantages of Double Layer Roll Forming MachineDouble layer roll forming machines offer several advantages over traditional manufacturing methods. Some of these advantages include:1. Increased EfficiencyBy producing two different profiles simultaneously, double layer roll forming machines significantly enhance production efficiency. This allows manufacturers to meet higher demand while reducing production time and costs.2. Cost-effectiveDouble layer roll forming machines eliminate the need for multiple machines or processes to produce different profiles. This saves on equipment costs and reduces labor requirements, making it a cost-effective solution for profile manufacturing.3. CustomizationWith adjustable rollers and dies, double layer roll forming machines offer great flexibility in producing customized profiles. Manufacturers can easily adjust the machine settings to meet specific requirements, allowing for greater product variety.4. High PrecisionDouble layer roll forming machines ensure high precision in profile manufacturing. The uniformity and accuracy of the forming process result in consistent product dimensions and quality, reducing waste and improving overall product performance.5. Time-savingThe continuous and automated nature of double layer roll forming machines saves significant time compared to manual or semi-automated processes. This enables manufacturers to meet tight deadlines and deliver products on schedule.ConclusionDouble layer roll forming machines are a valuable asset in various industries, offering increased efficiency, cost-effectiveness, and customization options. Their applications range from construction and automotive to HVAC and furniture manufacturing. By understanding the working principle and advantages of these machines, manufacturers can make informed decisions about integrating them into their production processes.Quote Inquiry

Categories

The Versatility and Efficiency of Glazed Tile Roll Forming MachinesGlazed tile roll forming machines have revolutionized the construction industry by providing a highly efficient and cost-effective solution for producing glazed tiles. These machines are designed to transform various types of raw materials into perfectly shaped and glazed tiles, making them an essential tool for any tile manufacturing business. In this article, we will explore the different aspects and benefits of glazed tile roll forming machines.What is a Glazed Tile Roll Forming Machine?A glazed tile roll forming machine is a specialized equipment used in the production of glazed tiles. It is a fully automated machine that takes raw materials, such as galvanized steel or aluminum, and transforms them into finished glazed tiles of various shapes and sizes. The machine operates by passing the raw materials through a series of rollers, which gradually shape and form the tiles. The final product is then cut to the desired length and undergoes a glazing process to achieve a smooth and glossy finish.The Benefits of Using Glazed Tile Roll Forming MachinesGlazed tile roll forming machines offer numerous advantages for tile manufacturers. Here are some of the key benefits:1. Increased EfficiencyBy automating the tile production process, glazed tile roll forming machines significantly increase efficiency. These machines can produce a large number of tiles in a short period, reducing labor costs and improving overall productivity. The automated nature of the machine also ensures consistent and precise tile production, minimizing errors and waste.2. Versatility in Tile DesignGlazed tile roll forming machines can produce tiles of various shapes, sizes, and designs. With customizable roller sets, manufacturers can easily switch between different tile profiles, offering versatility and flexibility to meet customer demands. This feature allows tile manufacturers to cater to a wide range of applications, from residential to commercial projects.3. Cost-Effective ProductionInvesting in a glazed tile roll forming machine can lead to significant cost savings in the long run. These machines require minimal maintenance and have a long lifespan, reducing operational costs. Additionally, the automated production process eliminates the need for manual labor, further lowering expenses. With the ability to produce large quantities of tiles in-house, manufacturers can also save on transportation and outsourcing costs.4. Improved Tile QualityGlazed tile roll forming machines produce tiles with exceptional quality and precision. The automated process ensures consistent tile dimensions, making installation easier and more efficient. The glazing process also guarantees a smooth and glossy finish, enhancing the visual appeal of the tiles. High-quality tiles not only increase customer satisfaction but also contribute to the reputation and success of tile manufacturers.5. Time-SavingManual tile production can be time-consuming and labor-intensive. Glazed tile roll forming machines simplify the production process, allowing manufacturers to save valuable time. By automating the manufacturing process, these machines eliminate the need for manual labor and repetitive tasks, enabling manufacturers to focus on other aspects of their business, such as marketing and product development.6. Environmentally FriendlyGlazed tile roll forming machines are designed with sustainability in mind. The production process generates minimal waste, and the machines can be integrated with recycling systems to reduce environmental impact. Additionally, the energy-efficient operation of these machines helps reduce energy consumption, making them a greener choice for tile manufacturing.7. Easy Operation and MaintenanceGlazed tile roll forming machines are user-friendly and require minimal training to operate. The machines are equipped with intuitive controls and interfaces, allowing operators to set parameters and monitor the production process easily. Routine maintenance is also straightforward, ensuring that the machines operate at their optimal performance levels.8. Competitive AdvantageInvesting in a glazed tile roll forming machine can give tile manufacturers a competitive edge in the market. The ability to produce high-quality tiles efficiently and cost-effectively allows manufacturers to offer competitive prices and meet tight project deadlines. This advantage can help attract more customers, generate higher profits, and establish a strong market position.9. Long-Term InvestmentA glazed tile roll forming machine is a long-term investment that offers a high return on investment. The durability and reliability of these machines ensure years of continuous operation without significant downtime or costly repairs. As the demand for glazed tiles continues to grow, manufacturers can capitalize on this investment and expand their business.10. Future InnovationsGlazed tile roll forming machines are constantly evolving with technological advancements. Manufacturers can expect future innovations that further enhance the efficiency, versatility, and sustainability of these machines. By staying updated on the latest developments in tile roll forming technology, manufacturers can continue to improve their production processes and stay ahead of the competition.glazed tile roll forming machine, glazed tile, roll forming machine, tile production, efficiency, versatility, cost-effective, tile design, tile quality, time-saving, environmentally friendly, easy operation, maintenance, competitive advantage, long-term investment, future innovationsGlazed Tile Roll Forming Machines: Efficiency and VersatilityDiscover the benefits of using glazed tile roll forming machines for efficient and cost-effective tile production. Explore the versatility, time-saving capabilities, and long-term advantages of these machines.Quote Inquiry

IntroductionA roof sheet roll forming machine is a valuable piece of equipment used in the construction industry to manufacture roof sheets with precision and efficiency. This machine plays a crucial role in the production process, offering numerous benefits to both manufacturers and end-users. In this article, we will explore ten key aspects of a roof sheet roll forming machine and how it contributes to the construction industry.1. Accuracy and PrecisionOne of the primary advantages of using a roof sheet roll forming machine is its ability to produce accurate and precise roof sheets. The machine is equipped with advanced technology that ensures consistent dimensions and shapes, resulting in high-quality products. This level of precision is essential for creating roof sheets that fit perfectly, reducing the risk of leaks and other structural issues.2. Cost EfficiencyInvesting in a roof sheet roll forming machine can significantly reduce production costs in the long run. By automating the manufacturing process, it eliminates the need for manual labor and reduces human errors. Additionally, the machine optimizes material usage, minimizing waste and maximizing production efficiency. This cost-saving aspect makes it an attractive choice for both small and large-scale manufacturers.3. Increased ProductivityA roof sheet roll forming machine can greatly enhance productivity in the manufacturing process. The machine operates at a high speed, producing a large volume of roof sheets within a short period. This increased productivity allows manufacturers to meet tight deadlines and fulfill customer orders promptly. It also enables them to take on more projects, ultimately boosting profitability.4. VersatilityWith a roof sheet roll forming machine, manufacturers have the flexibility to produce a wide range of roof sheet profiles. The machine can be easily adjusted to create different shapes, sizes, and designs to cater to various customer requirements. This versatility gives manufacturers a competitive edge in the market, as they can offer a diverse range of products to meet the demands of different construction projects.5. Durability and StrengthRoof sheets produced using a roll forming machine are known for their durability and strength. The machine ensures that the sheets are formed with uniform thickness and a consistent structure, resulting in enhanced strength and resistance to external factors such as harsh weather conditions. These robust roof sheets provide long-lasting protection to buildings, reducing maintenance costs in the long term.6. Time EfficiencyTime is a valuable resource in the construction industry, and a roof sheet roll forming machine helps save a significant amount of it. The machine operates efficiently, automating the entire production process from feeding raw materials to cutting finished roof sheets. This automation eliminates the need for manual handling and speeds up the manufacturing process, allowing manufacturers to complete projects faster and meet tight construction schedules.7. Consistency in QualityConsistency in product quality is of utmost importance in the construction industry. A roof sheet roll forming machine ensures that each roof sheet produced is of the same high quality. By maintaining consistent dimensions, shape, and structural integrity, the machine eliminates variations in product quality that may occur with manual production methods. This consistency instills confidence in customers and helps build a reputable brand.8. SafetyUsing a roof sheet roll forming machine promotes a safer working environment for operators and workers. The machine is designed with multiple safety features to prevent accidents and injuries. It eliminates the need for manual cutting and shaping, reducing the risk of cuts and other work-related hazards. Additionally, the machine's automated operation minimizes human interaction, further enhancing workplace safety.9. Ease of MaintenanceRoof sheet roll forming machines are designed for easy maintenance and long-term reliability. Regular maintenance checks and lubrication ensure the smooth operation of the machine, minimizing downtime and optimizing productivity. Additionally, most manufacturers provide comprehensive user manuals and technical support, making it easier for operators to troubleshoot minor issues and keep the machine in excellent working condition.10. Environmental FriendlinessAs sustainability becomes increasingly important in the construction industry, a roof sheet roll forming machine offers environmental benefits. By optimizing material usage and minimizing waste, the machine reduces the overall carbon footprint of the manufacturing process. Additionally, the use of energy-efficient components and technologies further contributes to environmental conservation.Quote Inquiry

What is a Roll Forming Machine and How Does it Work?A roll forming machine is a specialized piece of equipment used in the manufacturing industry to shape metal sheets into desired profiles. It is a continuous process that involves passing a metal strip through a series of rollers, gradually bending and forming it into the desired shape. This method is particularly efficient for producing long lengths of uniform shapes, making it ideal for industries such as construction, automotive, and appliance manufacturing.The Advantages of Using a Roll Forming MachineRoll forming machines offer numerous advantages over other metal forming methods. One of the key benefits is the ability to produce complex shapes with consistent accuracy and precision. The continuous nature of the process allows for high production speeds and reduces material waste. Additionally, roll formed parts typically have excellent strength and structural integrity, making them ideal for applications requiring durability and load-bearing capabilities.Types of Roll Forming MachinesThere are various types of roll forming machines available, each designed for specific applications. Some common types include:Single-stand roll forming machinesDouble-stand roll forming machinesCassette roll forming machinesTandem roll forming machinesCustom roll forming machinesApplications of Roll Forming MachinesRoll forming machines are widely used in a range of industries for different applications. Some common applications include:Roofing and sidingAutomotive body panelsStorage systems and shelvingFurniture and fixturesDoors and windowsFactors to Consider When Choosing a Roll Forming MachineWhen selecting a roll forming machine for your specific needs, there are several factors to consider:Material type and thicknessDesired profile and shape complexityProduction speed and volume requirementsFlexibility for future product changesQuality and reliability of the machineMaintenance and Safety Tips for Roll Forming MachinesProper maintenance and safety practices are essential for ensuring the longevity and safe operation of roll forming machines. Regular cleaning, lubrication, and inspection of the machine's components help prevent wear and damage. It is also crucial to follow all safety guidelines, including wearing appropriate personal protective equipment and ensuring proper installation and grounding of the machine.The Future of Roll Forming MachinesThe roll forming industry is continuously evolving, driven by advancements in technology and increasing demand for efficiency. Some emerging trends in roll forming machines include:Integration with automation and roboticsSmart sensors for real-time monitoring and quality controlSoftware advancements for faster design and productionEnergy-efficient and eco-friendly machine designsIntegration with Industry 4.0 principles for seamless data exchange and connectivityChoosing the Right Roll Forming Machine ManufacturerWhen investing in a roll forming machine, it is essential to choose a reputable manufacturer with a proven track record. Look for manufacturers with extensive experience in the industry, a wide range of machine options, and excellent customer support. Additionally, consider factors such as warranty, after-sales service, and availability of spare parts.The Cost of Roll Forming MachinesThe cost of a roll forming machine can vary significantly depending on factors such as machine type, size, complexity, and additional features. It is essential to consider the long-term return on investment rather than focusing solely on the initial cost. A high-quality machine may have a higher upfront cost but can provide greater productivity, reliability, and cost savings in the long run.Quote Inquiry